Zuschneidfelle – Meaning, Uses, Applications, Benefits & Complete Guide

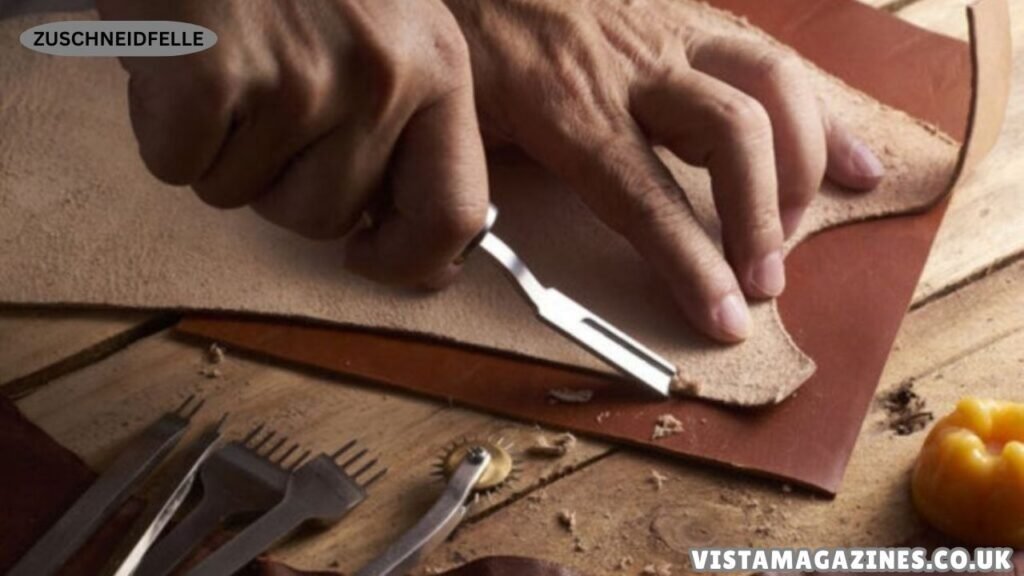

Zuschneidfelle is a specialized term that refers to cutting pelts, trimming hides, or prepared materials used for cutting and shaping purposes in various industries. The word zuschneidfelle originates from German, where “zuschneiden” means to cut or trim and “felle” refers to pelts or hides. Together, zuschneidfelle represents materials specifically prepared for cutting and further processing. These materials are commonly associated with leather production, upholstery, textile industries, and specialized crafts. In modern manufacturing, precision and efficiency are crucial, and zuschneidfelle plays an essential role in ensuring accurate material preparation. Whether used in leather goods production, fashion design, or industrial applications, zuschneidfelle supports consistent quality and optimized output. As global demand for leather and hide-based products continues to grow, understanding zuschneidfelle becomes increasingly important for manufacturers, designers, and suppliers alike.

Understanding the Meaning and Origin of Zuschneidfelle

The term zuschneidfelle reflects a functional concept rather than a brand or abstract idea. In traditional European craftsmanship, especially within German-speaking regions, cutting and preparing hides was a specialized skill. Zuschneidfelle refers to hides or pelts that are designated for precise cutting according to patterns and measurements. This process ensures that materials are efficiently used with minimal waste. Historically, leather artisans relied heavily on properly prepared zuschneidfelle to create garments, footwear, furniture coverings, and accessories. Over time, technological advancements introduced automated cutting machines and digital pattern systems, yet the fundamental concept of zuschneidfelle remains relevant. It still represents quality hides that are suitable for professional cutting and shaping. Understanding this term allows professionals to better communicate within global supply chains and specialized industries.

Industrial Applications of Zuschneidfelle

Zuschneidfelle is widely used in industries that rely on leather, hide, and heavy-duty fabric materials. The fashion industry is one of the primary users of zuschneidfelle, particularly in the production of jackets, bags, belts, and footwear. Designers depend on precisely prepared materials to ensure accuracy in pattern cutting. Upholstery manufacturing is another significant area where zuschneidfelle plays a key role. Sofas, chairs, automotive interiors, and luxury seating often require high-quality hides that can be cut with precision. Additionally, industrial protective equipment manufacturers utilize zuschneidfelle for gloves, aprons, and heavy-duty workwear. The durability of leather makes it suitable for demanding environments. Craft artisans and custom leatherworkers also depend on zuschneidfelle for small-scale production, where careful cutting ensures aesthetic appeal and structural integrity. In each of these industries, the quality of zuschneidfelle directly impacts the final product.

Types of Zuschneidfelle Used in Production

There are various types of zuschneidfelle depending on the source and treatment of the hide. Cowhide is one of the most commonly used materials due to its strength and versatility. Lambskin zuschneidfelle is valued for its softness and flexibility, making it ideal for garments and luxury goods. Goatskin offers a balance between durability and lightweight properties, making it popular for gloves and small accessories. Exotic hides, though less common, may also fall under the category of zuschneidfelle when prepared for specialized cutting. The preparation process typically includes cleaning, tanning, conditioning, and surface finishing. Tanning methods can vary, including vegetable tanning and chrome tanning, each affecting texture and durability. The choice of zuschneidfelle type depends on the intended application, budget considerations, and design requirements.

The Role of Zuschneidfelle in Precision Manufacturing

Precision manufacturing requires consistency and accuracy. Zuschneidfelle must meet specific thickness, texture, and flexibility standards to ensure uniform cutting. Modern cutting technologies, such as laser cutting and computer-controlled machines, rely on stable material quality. If zuschneidfelle varies significantly in density or elasticity, production errors can occur. Therefore, suppliers carefully grade hides before designating them as zuschneidfelle. Quality control processes include inspecting for blemishes, uneven surfaces, and structural weaknesses. By maintaining high standards, manufacturers can minimize waste and improve efficiency. The integration of technology has enhanced the way zuschneidfelle is utilized, but the foundational requirement remains the same: reliable material suitable for precise shaping.

Benefits of Using High-Quality Zuschneidfelle

Choosing premium zuschneidfelle offers numerous advantages. First, it ensures durability in the final product. High-quality hides maintain their strength and aesthetic appeal over time. Second, proper zuschneidfelle reduces material waste during cutting, maximizing resource utilization. Third, consistent texture and thickness simplify the production process, reducing the need for adjustments. Additionally, superior zuschneidfelle enhances customer satisfaction, as the finished product reflects craftsmanship and longevity. Businesses that prioritize quality materials often build stronger reputations and long-term client relationships. While premium zuschneidfelle may involve higher initial costs, the long-term benefits often outweigh the investment.

Sustainability and Ethical Considerations of Zuschneidfelle

In recent years, sustainability has become a major focus within the leather industry. Zuschneidfelle production is increasingly influenced by ethical sourcing and environmentally responsible tanning methods. Many manufacturers now emphasize traceable supply chains and reduced chemical usage. Vegetable tanning, for example, uses natural plant-based tannins instead of synthetic chemicals. Recycling and upcycling leather scraps also contribute to sustainability efforts. Consumers are more conscious about product origins, and companies that prioritize responsible zuschneidfelle sourcing often gain competitive advantages. Balancing tradition with environmental responsibility is essential for the future of the industry.

Maintenance and Handling of Zuschneidfelle

Proper storage and handling of zuschneidfelle are crucial to maintain quality. Hides should be kept in controlled environments with stable temperature and humidity levels. Excess moisture can cause mold, while dryness may lead to cracking. Before cutting, zuschneidfelle should be inspected and conditioned if necessary. Skilled professionals understand how to position patterns to avoid natural imperfections and maximize material efficiency. Long-term maintenance practices also include protective treatments that enhance durability and appearance. By following best practices, manufacturers can extend the lifespan of zuschneidfelle and maintain production consistency.

Market Demand and Future Trends for Zuschneidfelle

Global demand for leather products continues to influence the zuschneidfelle market. Luxury fashion brands, automotive manufacturers, and furniture producers consistently require high-quality cutting materials. Technological advancements in digital pattern design and automated cutting systems are shaping how zuschneidfelle is utilized. Additionally, innovation in alternative materials may influence market dynamics. However, genuine leather remains highly valued for its durability and natural appeal. As sustainability initiatives expand, suppliers are adapting processes to meet modern expectations. The future of zuschneidfelle will likely combine traditional craftsmanship with technological precision and environmental responsibility.

Conclusion: Why Zuschneidfelle Matters in Modern Industry

Zuschneidfelle represents more than just cutting hides; it embodies the foundation of precision, quality, and craftsmanship in multiple industries. From fashion and upholstery to protective equipment and artisanal goods, zuschneidfelle ensures reliable material preparation. Understanding its meaning, types, applications, and sustainability aspects provides valuable insight into modern manufacturing processes. As industries evolve and consumer expectations shift toward quality and ethical production, zuschneidfelle will continue to play a critical role. Its relevance lies in its ability to adapt to innovation while preserving traditional craftsmanship standards.

Also read: Meaning, Origins, Uses, Trends & Complete Guide to Bardoek