Boeing Drafting Room Inside the Historic Workspace that Shaped Modern Aviation

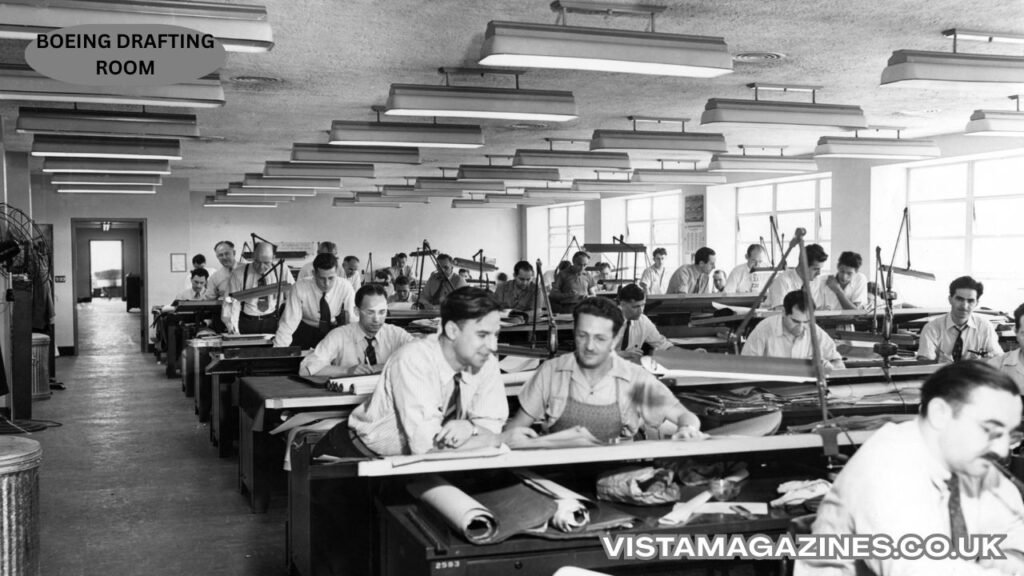

The phrase boeing drafting room evokes an image of precision, creativity, and engineering discipline. Long before advanced 3D modeling software and digital aerospace simulations became common, the boeing drafting room served as the birthplace of aircraft designs that would change global aviation. It was a unique environment where engineers, draftsmen, and designers collaborated to translate aerodynamic ideas into detailed blueprints. The boeing drafting room represents a key evolutionary stage in industrial engineering culture, a place where calculations, artistry, and physical drawing techniques merged to define the future of flight. For many decades it remained the symbolic heart of Boeing’s engineering operations, combining structured workflow with a distinct creative workspace that belonged only to the world of aviation pioneers.

Origins and Historical Significance of the Boeing Drafting Room

To understand the historical significance of the boeing drafting room, it is important to recognize the era in which it rose to prominence. Early aviation development demanded an experimental mindset, yet safety and precision were critical. The boeing drafting room became the intermediary step between conceptual sketches and physical aircraft components. Every fuselage panel, wing surface, rivet map, and mechanical assembly had to be drawn meticulously by hand. The drafting room helped transform rough aerodynamic ideas into validated production specifications that could be manufactured, tested, and flown. In essence, the boeing drafting room acted as both a laboratory for conceptual engineering and a factory for technical data. Engineers who entered the boeing drafting room understood that the decisions they made on paper would eventually become airborne machines carrying pilots, passengers, and military equipment.

Furthermore, the boeing drafting room outlines a historical era when manual drafting tools such as t-squares, protractors, compasses, French curves, vellum sheets, blueprints, and slide rules were central to engineering work. This period highlights the craftsmanship of engineering before digital transitions. The boeing drafting room therefore stands not only as an industrial space but as an educational and cultural institution, passing down generations of drafting techniques. Young engineers learned alongside veterans, absorbing not only technical knowledge but also attitudes regarding responsibility, precision, and disciplined design behavior. This knowledge transfer made the boeing drafting room a living school of aviation engineering, where each project created new lessons for the next wave of aircraft designers.

Workflow and Engineering Methodology within the Boeing Drafting Room

Inside the boeing drafting room, workflow followed a carefully structured approach. Aircraft concepts typically began with aerodynamic and manufacturing considerations, then moved into detailed component drawings. At each stage the boeing drafting room served as the documentation hub. The first layer of work involved conceptual drawings illustrating the aircraft’s shape, wing loading calculations, and general internal arrangement. The second layer demanded dimensionally accurate component drawings that machinists and assembly technicians could physically build. The boeing drafting room produced these layered outputs in a way that reduced manufacturing errors and ensured repeatability.

Measurement accuracy inside the boeing drafting room was uncompromising. Standards of tolerance dictated how components should fit together under mechanical stress, air pressure, and environmental variation. Draftsmen wrote out materials, thicknesses, hole spacing, and fastener requirements directly onto drawings. Concurrency played an important role; structural engineers, aerodynamicists, and systems engineers often examined the same drawings simultaneously. At the center of this collaboration was the boeing drafting room, which acted as both a collaboration zone and a data repository. If a fuel line needed to be rerouted, or a wing spar reinforced, the drafting room reflected the modifications so the change would cascade through production lines.

The drafting room also relied on hierarchical review structures. Senior engineers reviewed drawings for safety, manufacturability, and compliance with requirements. Revisions were expected, and the boeing drafting room culture valued clarity over speed. A typical blueprint might undergo dozens of refinements before final release. This iterative approach formed the backbone of Boeing’s engineering success, linking careful thought with thorough documentation.

Tools, Materials, and Technical Instruments in the Boeing Drafting Room

Tools were foundational to the identity of the boeing drafting room. Manual drafting demanded mechanical precision through analog instruments. Drafting boards were calibrated for flatness and equipped with parallel bars to maintain consistent drawing angles. T-squares ensured vertical and horizontal alignment, while French curves smoothed aerodynamic surfaces. Protractors handled angles, while compasses drew arcs needed for wing tips, fuselage transitions, and instrument bezels.

Paper quality mattered greatly inside the boeing drafting room. Vellum sheets resisted smudging and allowed ink to flow evenly. Ink pens and technical pencils provided different line weights for outlines, hidden structures, centerlines, and annotations. Erasers were specialized to avoid damaging vellum, and templates provided standardized holes and fittings for consistent interpretation. Eventually, blueprint machines transformed these drawings into field copies for assembly floors, further emphasizing the role of the boeing drafting room as a bridge between design and physical reality.

Calculations also played a major role. Before computer software, mathematical results came from slide rules, punch-card calculators, and logarithmic tables. Engineers inside the boeing drafting room trusted their own calculations because an incorrect wing loading or stress value had consequences for safety and airworthiness. Drafting culture demanded accuracy in mathematics as much as artistry in drawing.

The Culture and Human Element of the Boeing Drafting Room

The boeing drafting room was not only a place filled with tables and tools; it was a social and intellectual environment with its own culture. Engineers and draftsmen often built strong camaraderie through shared challenges. For many, the boeing drafting room felt like a workshop where each drawing carried personal responsibility. Individuals took pride in the aircraft they helped create, even if their names never reached the public.

Mentorship was central to drafting room culture. Newcomers started with simpler components and gradually advanced to complex systems. Veterans offered guidance, corrections, and stories about past aircraft models. This human element turned the boeing drafting room into a cultural hub for aviation knowledge. Engineers learned how to think about airflow, mechanical stress, cockpit ergonomics, and repairability. They learned to consider the needs of pilots, technicians, and manufacturing personnel, making the drafting room a multi-perspective training ground.

The work pace inside the boeing drafting room was intense, especially during periods of aviation growth. Deadlines tied to government contracts and commercial orders pushed teams to work strategically, often late into the evening. Yet despite the pressure, the culture demanded precision before speed. One incorrect drawing could disrupt entire assembly lines or compromise safety. As a result, the boeing drafting room developed a reputation for disciplined professionalism.

Transition from Manual Drafting to Digital Engineering

With advancements in computer graphic systems, the boeing drafting room began a major transformation. Though early digital tools lacked the tactile precision of manual drafting, their ability to store, revise, and simulate designs quickly became invaluable. Over time, the manual drafting boards were replaced by CAD stations and digital workflows. While the modern engineering environment is vastly different, the legacy of the boeing drafting room persists in software methodologies, documentation systems, and design culture.

This transition highlights how the boeing drafting room represents a bridge from analog engineering to digital aerospace design. Even in the age of simulation software and 3D modeling, the foundational principles created in the drafting room remain relevant. Layers, revision control, tolerances, material specs, and collaborative review cycles are still core to aerospace engineering processes.

Educational Value and Legacy of the Boeing Drafting Room

Today, the boeing drafting room stands as a symbol of traditional engineering education. Students studying aerospace design learn the importance of accurate documentation, consistent dimensioning, and clear communication. Many engineering programs still teach manual drafting fundamentals to reinforce spatial understanding and geometric visualization. The legacy of the boeing drafting room reminds modern engineers that tools may change, but principles endure.

Beyond education, the drafting room embodies the history of human ingenuity. Every aircraft that ever soared above continents began as a drawing. Before digital simulations, before composite materials, there were blueprints and vellum sheets. The boeing drafting room preserved these milestones, forming an engineering heritage that shaped commercial aviation, defense technology, and global transportation patterns.

Symbolic Meaning of the Boeing Drafting Room in Aviation History

The boeing drafting room symbolizes precision, discipline, collaboration, and innovation. It stands for the idea that complex technology originates from human imagination supported by systematic processes. It also highlights the unsung contributions of draftsmen, engineers, and designers whose work formed the backbone of aviation progress. Without the boeing drafting room, many of the aircraft that defined world travel, air defense, and industrial logistics might never have reached production.

The symbolic meaning of the boeing drafting room therefore extends beyond Boeing itself. It represents an entire era of industrial engineering where careful documentation determined the fate of major innovations. It represents a philosophy that enduring technology arises through analysis, revision, teamwork, and attention to detail.

Conclusion

The boeing drafting room remains a historically significant concept in the evolution of aviation design. It was far more than a workspace filled with drawing boards; it was a center of collaboration, mentorship, technical calculation, and industrial creativity. The drafting room produced not only blueprints but also engineering culture. It shaped the practices of aerospace documentation, production planning, and multi-disciplinary collaboration. Even today, as digital engineering dominates the aircraft design process, the legacy of the boeing drafting room continues in the form of engineering standards, documentation methods, and design philosophies that govern modern aviation.

Throughout its history, the boeing drafting room became a foundation for the creation of aircraft that connected nations, influenced military operations, and defined aviation eras. It taught generations of engineers that accuracy, clarity, and disciplined thought are essential to innovation. It remains a story of how human intellect and manual tools combined to build machines capable of conquering the skies. The boeing drafting room stands as one of the silent forces behind aerospace history, serving as a reminder of how big technological leaps often begin with pencils, rulers, and remarkable imagination.