Spezialbohrgetriebe Function, Design and Industry Guide

Modern industrial production relies heavily on precision engineering and durable mechanical components. One such specialized component is the spezialbohrgetriebe, a German term referring to a specialized drilling gearbox. In manufacturing, mining, construction, and heavy industry, drilling systems must operate with accuracy, torque control, and long-term reliability. This is where spezialbohrgetriebe plays a critical role.

Unlike standard gearboxes, a spezialbohrgetriebe is designed specifically for drilling applications. It handles high loads, maintains rotational stability, and ensures consistent torque transmission. These gear systems are built to perform under demanding conditions, including metal fabrication, deep drilling, and automated CNC processes.

This comprehensive guide explains what spezialbohrgetriebe is, how it works, where it is used, and why it is essential in industrial operations. Whether you are an engineer, technician, or business owner, understanding this component helps clarify its importance in modern machinery.

What Is Spezialbohrgetriebe

The term spezialbohrgetriebe combines three German words: “Spezial” (special), “Bohr” (drill), and “Getriebe” (gearbox). In simple terms, it refers to a gearbox specifically engineered for drilling machines.

A gearbox is responsible for transmitting mechanical power from a motor to an output shaft. In drilling systems, precise speed control and torque regulation are essential. A spezialbohrgetriebe ensures that the drill bit rotates at the correct speed while maintaining sufficient force to cut through materials.

Unlike general-purpose gear systems, this specialized gearbox is optimized for:

- High torque loads

- Variable speed settings

- Continuous operation

- Precision alignment

- Durability in harsh environments

Its purpose is to maximize efficiency and minimize mechanical stress during drilling processes.

How a Spezialbohrgetriebe Works

At its core, a spezialbohrgetriebe operates by transferring power from an electric motor or hydraulic drive to the drilling mechanism. The internal gear configuration adjusts rotational speed and torque depending on the task.

When drilling into hard materials such as steel or reinforced concrete, lower speeds with higher torque are required. For softer materials, higher speeds may be more effective. The gearbox manages this balance automatically or through operator control.

Inside the housing, precision-cut gears mesh together to reduce speed while increasing torque. Bearings and lubrication systems ensure smooth rotation and reduce friction.

This controlled mechanical transmission guarantees accurate drilling performance.

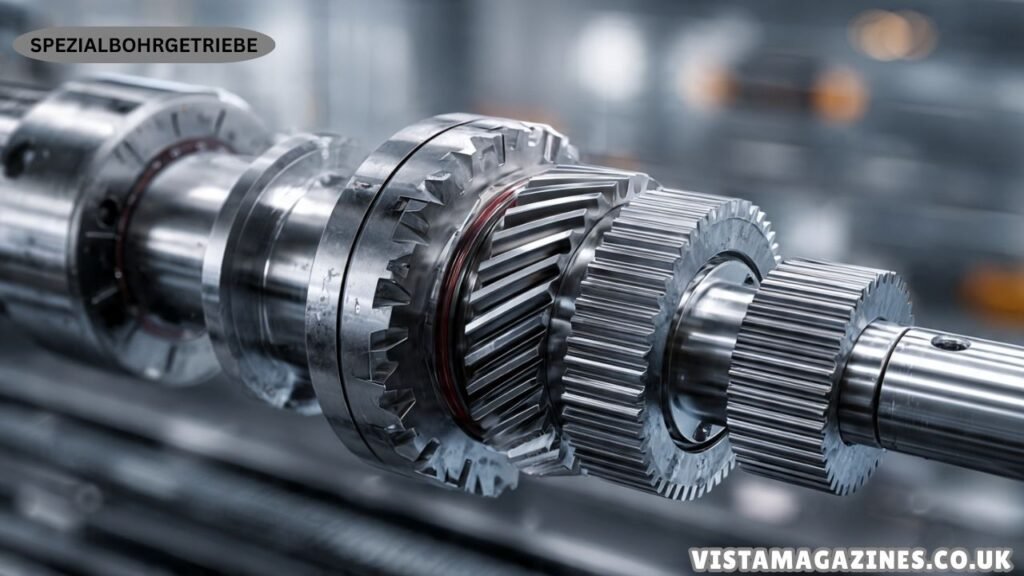

Key Components of a Spezialbohrgetriebe

A spezialbohrgetriebe consists of several important components that ensure durability and precision.

Gear Set

High-strength gears transmit torque while maintaining alignment under load.

Housing

The outer casing protects internal components from dust, debris, and vibration.

Bearings

Support rotating shafts and reduce friction during operation.

Lubrication System

Maintains smooth performance and prevents overheating.

Shaft Mechanism

Connects the motor output to the drilling spindle.

Each component must meet strict industrial standards to ensure long-term reliability.

Industrial Applications

Spezialbohrgetriebe systems are widely used across multiple industries. Their versatility and durability make them essential in heavy-duty environments.

Manufacturing

CNC drilling machines rely on specialized gearboxes for precise hole formation in metal parts.

Construction

Drilling systems used for foundations and structural work depend on torque-stable gear transmission.

Mining

Heavy rock drilling operations require robust gear systems capable of withstanding extreme stress.

Automotive Industry

Production lines use specialized drilling gearboxes for engine and chassis components.

Aerospace Engineering

High-precision drilling in aircraft manufacturing demands stable and accurate rotation control.

These applications highlight how critical spezialbohrgetriebe is in maintaining industrial productivity.

Advantages of Using Spezialbohrgetriebe

Choosing a spezialbohrgetriebe over a standard gearbox offers several advantages.

Precision Control

Ensures accurate hole placement and consistent drilling depth.

High Torque Output

Allows drilling through tough materials without performance loss.

Durability

Designed to handle continuous industrial workloads.

Reduced Maintenance

Specialized design minimizes wear and tear.

Operational Efficiency

Optimized torque transmission reduces energy waste.

These benefits contribute to cost savings and improved production outcomes.

Design and Engineering Considerations

Engineers must carefully design spezialbohrgetriebe systems to match specific applications. Factors considered include:

- Material strength

- Heat resistance

- Gear ratio

- Noise reduction

- Vibration control

Custom designs may be required for unique drilling environments. For example, underwater drilling equipment needs corrosion-resistant materials, while mining operations require reinforced gear structures.

Precision engineering ensures that the gearbox integrates seamlessly with existing machinery.

Maintenance and Longevity

Although spezialbohrgetriebe systems are durable, proper maintenance is essential for maximum lifespan.

Regular inspections should check:

- Lubrication levels

- Gear alignment

- Bearing condition

- Temperature levels

- Noise irregularities

Preventive maintenance reduces downtime and extends operational life.

High-quality gear materials combined with proper care can allow these systems to function efficiently for many years.

Technological Advancements

Modern spezialbohrgetriebe systems incorporate advanced technology to improve performance.

Some innovations include:

- Smart sensors for temperature monitoring

- Automated lubrication systems

- Noise-reduction gear profiles

- Lightweight yet durable materials

- Enhanced corrosion resistance

These upgrades enhance reliability and safety in industrial environments.

Automation integration also allows better monitoring and data collection for predictive maintenance.

Cost Efficiency and Business Value

While specialized gearboxes may require higher initial investment, they often deliver long-term savings.

Benefits include:

- Reduced equipment failure

- Fewer production interruptions

- Lower maintenance expenses

- Higher precision output

- Increased operational lifespan

For businesses relying on drilling accuracy, investing in a spezialbohrgetriebe can significantly improve productivity and profit margins.

Why Spezialbohrgetriebe Is Essential in Modern Industry

In today’s manufacturing and construction sectors, precision and reliability are non-negotiable. Drilling errors can result in costly material waste or structural weaknesses.

Spezialbohrgetriebe systems ensure stability under pressure. They allow machines to operate consistently without compromising performance.

As industries demand faster and more accurate production methods, specialized mechanical components become increasingly important.

This gearbox solution represents the evolution of industrial engineering.

Conclusion

Spezialbohrgetriebe is a specialized drilling gearbox designed to provide precise torque control, durability, and high performance in demanding industrial applications. From manufacturing and construction to mining and aerospace, it plays a critical role in maintaining operational efficiency.

By combining strong materials, precision engineering, and optimized gear ratios, spezialbohrgetriebe systems deliver reliable results even under extreme conditions. Although maintenance remains important, their robust design minimizes downtime and maximizes productivity.

In modern industry, where accuracy and efficiency drive success, spezialbohrgetriebe stands as an essential mechanical solution for advanced drilling operations.

Also read: Cloudysocial Minison Social Media Growth Platform Guide